|

Translation may take a few seconds.

The word, "tungsten" denotes a substance of high density, and is derived from the Swedish language, "tung", meaning "heavy," and "sten", meaning "stone." The chemical symbol for tungsten is W, which stands for wolfram. The name came from medieval German smelters, who found that tin ores containing tungsten had a much lower yield. It was said that the tungsten devoured the tin "like a wolf". Pure tungsten metal was first isolated by two Spanish chemists, the de Elhujar brothers in 1723. General Information

Tungsten has the highest melting point of any metal, and at temperatures over Our Tungsten can now also be plated. Main Tungsten Properties

Applications Tungsten has become an essential material for a wide variety of applications due to its high melting point and high density. Only gold, platinum, and a few other rare and expensive metals have similar densities. Tungsten has many uses, but its two primary applications are as follows:

Uses in the PM Industry

Tungsten is often alloyed with nickel, copper, and iron, creating a family of materials with extremely useful properties.

These alloys are fabricated by powder metallurgical techniques and are routinely machined by conventional methods such as

turning, milling, grinding, polishing, drilling and tapping.

Absorption of x-rays and gamma radiation is in direct proportion to the density of the shielding material. Some tungsten

alloys are more than 1.5 times as effective as lead and provide extremely efficient protection; particularly where space is

limited. Such applications include radioactive source containers, syringe covers for radioactive isotope injection,

collimators and shielding blocks for high-energy cancer therapy machines, and shields for oil well logging instrumentation.

Twice as heavy as steel and more than 50% heavier than lead, tungsten high-density alloys have found wide acceptance where

a concentrated mass is required in a limited space for such applications as counter weights. Tungsten has a large variety of other uses, some of which are listed below. Summary of Tungsten Heavy Alloy Applications: Uses in the Plastic Industry

When Tungsten powder is mixed with suitable polymers, the process used offers many advantages:

Parts made from tungsten-filled polymeric compounds can look, feel, and often replace metallic components. These components are economically manufactured through the widely-used injection-molding process. Intricacy, high density, stiffness, cost efficiency and durability are just a few of the features of these compounds.

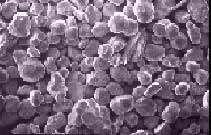

Tungsten Powders

Tungsten solids are sintered using virgin tungsten powder, which has a density of 4 to 7 g/cc. Only once sintered, does it

obtain its high density. The following tungsten powders are available:

| |||||||||||||||||||||||||||||||

|

Tungsten Heavy Powder, Inc. is the manufacturer of special tungsten powders made from sintered tungsten parts.

|

|

Home | About Us | Poly Kits | Products | Lead Replacement | Applications | About Tungsten | FAQ | Contact Us |

| © Copyright 2001-2003 Tungsten Heavy Powder, Inc. All rights reserved. This site designed and maintained by SEO Pros. |